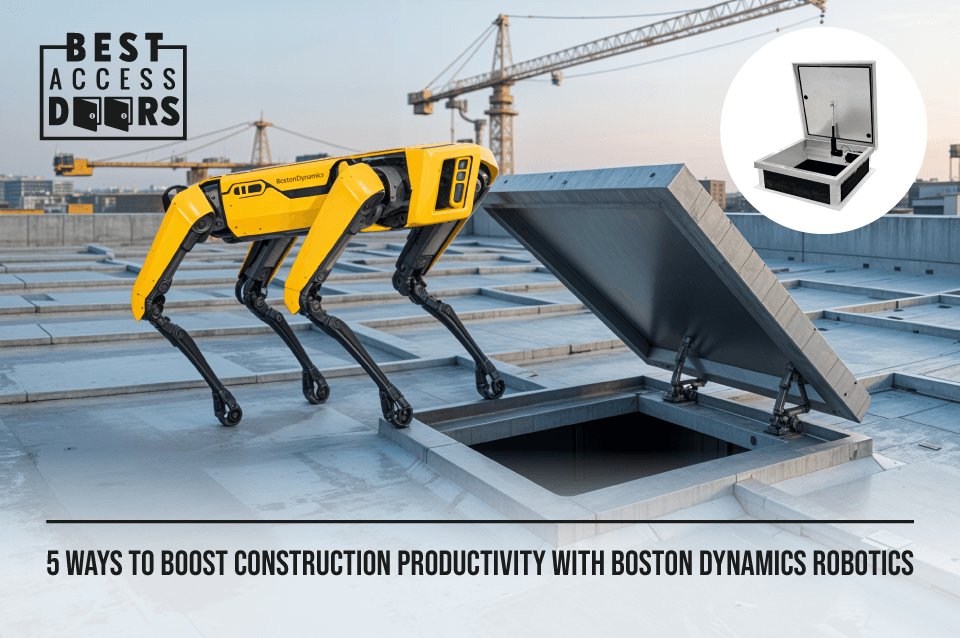

5 Ways to Boost Construction Productivity with Boston Dynamics Robotics

Posted by Best Access Doors on 12th Sep 2024

The construction industry is rapidly adopting new technologies to enhance productivity and efficiency. Boston Dynamics' robotics, particularly the Spot robot, are at the forefront of this technological revolution. Here are five ways these innovative robots boost construction productivity and how Best Access Doors' BA-EA-ARH Electric Actuation Aluminum Roof Hatch complements these advancements.

#1: Automated Inspections

Robotics technology, such as Boston Dynamics' Spot, performs inspections faster and more accurately than human workers. Spot can navigate complex environments, capturing detailed data using integrated sensors and cameras. Turner Construction, for instance, has cut inspection time by over 95% using Spot for autonomous data capture and 360° virtual walkthroughs, ensuring consistent and accurate progress tracking.

#2: Material Handling

Robots can significantly improve the efficiency of material handling on construction sites. They are designed for logistics and material movement and can easily transport heavy loads. By automating the transportation of materials, robots help streamline workflows, reduce downtime, and enhance overall productivity.

#3: Precision Work

Precision is crucial in construction, and robots perform highly accurate tasks. Boston Dynamics' robots can execute precise construction tasks, such as drilling, welding, and assembly, minimizing human error and ensuring high-quality results. This precision helps maintain project timelines and reduces the need for costly rework.

#4: Safety Monitoring

Worker safety is a top priority in construction, and robotics can play a vital role in enhancing it. Boston Dynamics' Spot can be equipped with sensors to monitor construction sites for potential hazards, ensuring workers are alerted to dangerous conditions in real-time. This constant monitoring helps prevent accidents and maintain a safer work environment.

#5: Labor Savings

One of the most significant advantages of incorporating robotics into construction is reducing manual labor. Robots can handle repetitive and strenuous tasks, allowing human workers to focus on more complex and value-added activities. This shift lowers labor costs and improves overall job satisfaction and productivity.

Enhancing Productivity with Best Access Doors' BA-EA-ARH Electric Actuation Aluminum Roof Hatch

Best Access Doors is committed to providing solutions that complement advancements in construction technology. The BA-EA-ARH Electric Actuation Aluminum Roof Hatch is designed to offer automated access and seamlessly integrate with Boston Dynamics' robotics' productivity-boosting capabilities.

Features and Benefits

- Electric Actuation: The BA-EA-ARH features electric actuation to enhance opening and closing and reduce the need for manual operation.

- Enhanced Efficiency: With electric actuation, the roof hatch can be operated quickly and efficiently, saving time and labor.

- Durability and Safety: Constructed from high-quality aluminum, the hatch is durable and provides a safe access point for inspection and maintenance tasks.

Integrating automated access solutions like the BA-EA-ARH Electric Actuation Aluminum Roof Hatch can enhance productivity, reduce labor costs, and improve efficiency at construction sites.

In conclusion, the combination of Boston Dynamics' cutting-edge robotics and Best Access Doors' innovative products offers a powerful synergy that significantly boosts construction productivity. Embracing these technologies ensures that construction projects are completed faster, safer, and cost-effectively.

If you have questions or would like to place an order, please call us at 1-800-483-0823 to get started!

Share our story - the 2025 version is available

Feedback

Feedback