How Offsite Construction Benefits Your Architectural Projects in Big Ways

Posted by Best Access Doors on 12th Jun 2024

Offsite construction, also known as prefab architecture or modular construction, offers architects a cost-effective and efficient alternative to traditional methods. It allows them to incorporate building components like wall panels, floor systems, and roof trusses in factories.

In this article, we’ll discuss the key benefits of offsite construction, including enhanced quality and efficiency, design flexibility, sustainability, and safety. We'll also discuss specific examples and techniques that make offsite construction a game-changer for modern architectural projects.

Quality and Efficiency Amplified

Factory-controlled environments revolutionize construction by guaranteeing precision and efficiency in every operation through state-of-the-art robotic assembly lines and automated quality control systems. Standardized processes, including automated assembly lines, cutting-edge equipment, and stringent quality control measures, play a crucial role in ensuring the success of offsite construction projects.

Offsite construction eliminates the risk of human error and inconsistencies on dynamic construction sites, resulting in higher-quality final products. Factory settings allow for thorough quality checks, including dimensional accuracy assessments, material strength tests, and visual inspections at each production stage, reducing the likelihood of defects that could arise during on-site construction.

Concurrent manufacturing, a key aspect of offsite construction, allows for the simultaneous production of various building components, streamlining the overall building process and reducing project timelines. This also reduces environmental impact by reducing material waste through precise cutting techniques and pre-determined material requirements. This results in cost savings and a more sustainable construction method than traditional on-site methods.

Offsite construction elevates quality control through standardized processes, advanced equipment, and meticulous inspections. This leads to more rapid project completion times and potentially lower overall costs, resulting from the efficiency gains from concurrent manufacturing and minimized waste.

Design Unleashed

Offsite construction is a revolutionary approach that allows architects to create unique and innovative structures without the constraints of traditional on-site construction methods. It enables the creation of various building components such as curved elements, detailed features, and modular systems through prefabrication.

Building components can be manufactured in a controlled environment, adding visual interest and design complexity to the final structure. Offsite construction also facilitates modular building components, allowing architects to create buildings with high design flexibility and customization.

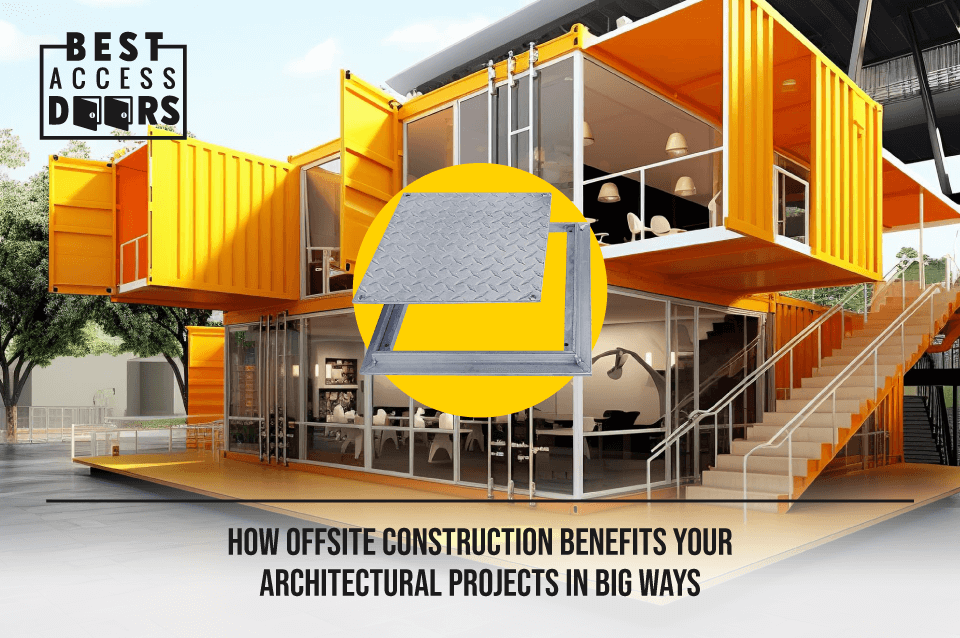

For instance, architects can design buildings that incorporate prefabricated floor hatches, like the BA-RFD removable diamond plated floor hatch. These hatches offer convenient access to underfloor utilities or building services, removing the necessity for on-site construction and maintaining consistent aesthetics. Such design flexibility empowers architects to bring their creative visions to life by enabling the realization of intricate and innovative design elements in offsite construction projects.

The success of these intricate designs relies on the collaborative efforts of architects, who provide creative vision; engineers, who ensure structural integrity; and factory experts, who implement manufacturing expertise.

Advanced Computer-Aided Design (CAD) tools and 3D models are crucial—translating the architect's creative intent into a structurally sound and aesthetically pleasing building. This collaborative approach ensures that offsite construction eliminates on-site limitations.

Sustainable Solutions

Offsite construction is a sustainable approach focusing on efficiency, design freedom, and resource utilization. It minimizes waste through precise cutting techniques and pre-determined material requirements, reducing the need for adjustments or trimming.

Factory-controlled environments optimize resource usage through dedicated management and recycling of excess materials. Wood scraps, for example, can be repurposed for smaller components, and excess packaging materials can be recycled within the facility.

Prefabricated building components can be manufactured using a high ratio of recycled materials, reducing the need for virgin materials and lowering the building's overall environmental footprint. Including energy-efficient features, like pre-installed insulation panels and solar control properties, significantly enhances the energy efficiency of buildings constructed through offsite methods.

By utilizing precise manufacturing techniques, efficient recycling initiatives, and sustainable prefabricated components, offsite construction establishes itself as a sustainable building approach that minimizes waste and promotes environmental responsibility.

Safety and Smoke Control

Offsite construction prioritizes safety by implementing stricter safety protocols, reducing reliance on heavy machinery on-site, and utilizing controlled factory environments—which can lead to a lower accident rate compared to traditional construction sites.

Moreover, offsite construction can integrate prefabricated smoke vents as safety features. These prefabricated smoke vents can be strategically placed to ensure efficient smoke evacuation during a fire emergency. This enhances building and occupant safety by facilitating rapid smoke and heat removal, ensuring clearer evacuation routes, and aiding fire suppression efforts.

By integrating these sustainable practices and safety features, offsite construction establishes itself as a responsible building approach that minimizes waste, prioritizes environmental responsibility, and enhances building safety.

Elevating Architecture: The Future With Offsite Construction

Offsite construction revolutionizes the industry, offering enhanced construction efficiency, faster project timelines, and potentially lower costs. It empowers architects by allowing the prefabrication of complex elements, fostering innovation, and pushing architectural boundaries. Offsite construction also prioritizes sustainability by minimizing material waste and integrating prefabricated components made from recycled materials and energy-efficient designs.

Additionally, offsite construction prioritizes safety by implementing stricter safety protocols, reducing reliance on heavy machinery on-site, and utilizing controlled factory environments, which can lead to a lower accident rate compared to traditional construction sites.

Ready to revolutionize your next architectural project with the efficiency of offsite construction? Browse our extensive selection of high-quality access doors, perfect for integrating seamlessly into your offsite construction plans. Connect with us to request a quote or call us at (800) 483-0823. Our team of experts is ready to answer your questions.

Share our story - the 2025 version is available

Feedback

Feedback