How Pressure Affects Injection Molding: Key Insights and Best Practices

Posted by Best Access Doors on 31st Jul 2024

Injection molding is used for making plastic parts. First, it involves melting plastic pellets and then the molten polymer is injected into a mold. The mold shapes the plastic into the desired form.

Finally, when it cools, the mold opens and out comes the part. However, for this process to run smoothly, pressure has to be applied. Hence, pressure plays a very vital role in injection molding.

The right pressure ensures that the plastic will fill up fully in every part of the mold. Pressure that is too low may result in the production of a defective part, just like too much pressure may damage either the mold or the part itself. Proper control of the right pressure makes a high-quality plastic part.

Types of Pressure in Injection Molding

Different kinds of pressure are needed to develop quality plastic parts in injection. Each pressure plays a distinct role in ensuring that the plastic fills the mold properly and there are no defects in the final product. These pressures have a very significant role in optimizing the injection molding process.

Some of the key types of pressure in injection molding include the following:

- Injection Pressure

- Holding Pressure

- Back Pressure

1. Injection Pressure

Injection pressure is the force used to push melted plastic into a mold. The said pressure should be high enough to push the plastic into all the parts of the mold. If the pressure is too low, then plastic may not fill the mold fully, which will create flaws in the final part. High injection pressure fills up the mold quickly and efficiently.

2. Holding Pressure

Next comes the holding pressure, which is applied after the initial injection. The plastic will fill up the mold before holding pressure holds it in place as it cools. This action ensures that the plastic does not flow back from the mold.

The air bubbles inside the plastic got compacted; thus, the holding pressure removed it and reduced shrinkage. Hence, the right holding pressure will ensure a quality, strong final part.

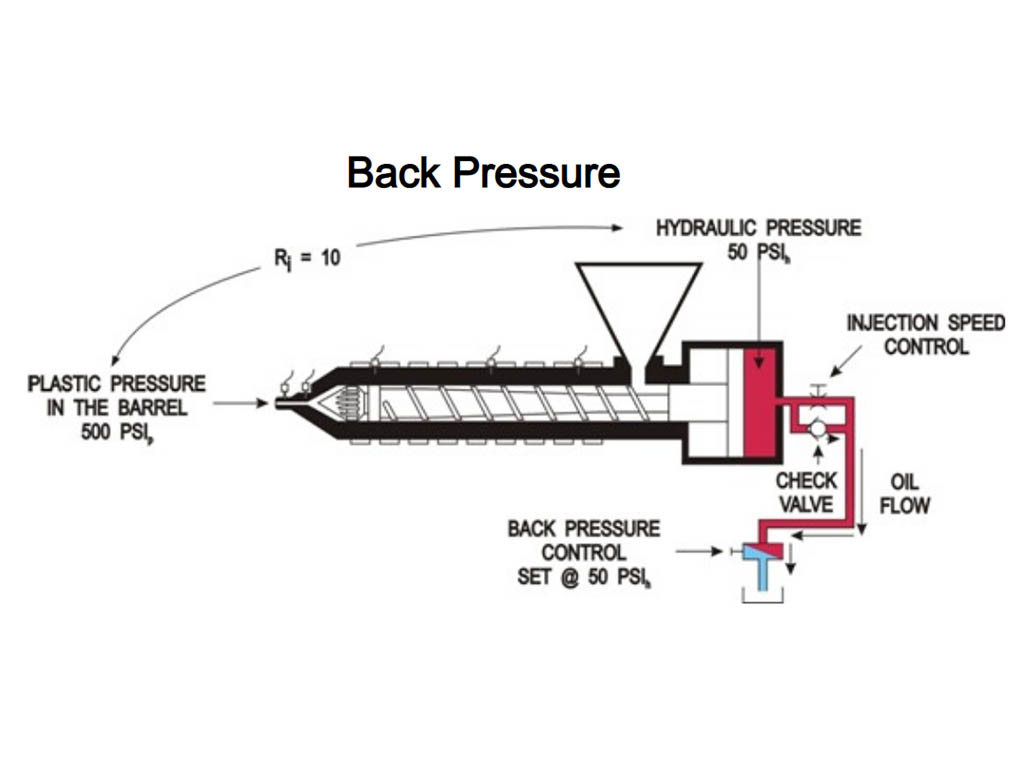

3. Back Pressure

Back pressure is applied during melting and mixing in the injection barrel. This pressure involves the right amount of force that can hold the plastic at the right density and integrity while it is in a molten state, ensuring good mixing of plastic with no air pockets, which could become CAVs later during any injection.

Back pressure also affects the temperature as well as the viscosity of the plastic. Proper back pressure ensures a smooth, defect-free build-up of the part.

Role of Injection Pressure

Understanding the role of injection pressure is key, especially when it comes to custom injection molding where accuracy is paramount.

How Injection Pressure Affects Filling of the Mold

Injection pressure forces the melted plastic into the mold cavity. The greater the pressure, the more certain one can be that the plastic will flow to all areas of the mold, including very minute details.

Too little pressure will fail to adequately fill the mold, resulting in shot shots or incomplete parts. Proper injection pressure ensures that a mold will be filled, resulting in a shape with a repetitive configuration.

Effects on Part Quality and Precision

The right injection pressure is paramount in producing high-quality parts with precision. High pressure allows for the elimination of entrapped air bubbles and voids within the plastic.

Making sure a densely packed plastic material ends up creating parts that are more solid and durable. The way this gives way to precise dimensions for every part is important, as it will be intended to fit together or have tight tolerances. Proper pressure all along the processing pathway helps produce final parts conforming to specifications and standards.

Back Pressure in Injection Molding (Image Source: Jazzmold)

Custom Injection Molding

In custom injection molding, certain part designs and features need to be realized. Injection pressure helps in the production of the custom requirements in this regard. It produces parts with complex designs and geometry accurately.

Custom molds usually require tight control over the injection pressure so that the final product matches perfectly with the design specification. Proper management of the pressure produces high-quality, precise, and custom-molded parts.

Influence of Holding Pressure

Holding pressure in injection molding is an important feature that holds the shape and stability of the part as it is cooling in the mold. The pressure holds plastic in the mold because it's cooling and solidifying. This will prevent the plastic from flowing back out of the mold, thus holding the shape of the part.

Proper holding pressure is also impactful in the achievement of desired dimensions and tolerances. This stability goes a long way in making parts that are designed to fit together or meet any other requirement in the design.

Prevention of Injection Molding Defects: Sink Marks and Voids

Sink marks and voids are some of the common injection molding defects you can avoid in the following ways:

Sink Marks

Sink marks are small depressions on the surface of the part. They occur because of uneven cooling and shrinkage of plastic. Proper holding pressure will help fill these gaps, which will reduce the occurrence of sink marks.

Voids

Voids are small pockets of air that are trapped in the plastic. It weakens the part where it could lead to its failure. Holding pressure packs, the plastic squeezes out air bubbles and avoids the creation of voids. The cool-down phase and high holding pressure ensure quality parts.

Examples from Injection Molding Manufacturers

Many injection molding manufacturers emphasize maintaining pressure. For example, Arburg or Engel will require one to maintain exact pressures. Advanced technology in these machines caters to the provision of the right holding pressure to ensure the lowest possible occurrence of defective parts.

Another example is Milacron, which runs on advanced software that checks and sets the holding pressure in real-time.

Back Pressure Management

Back pressure is applied to the plastic as it melts and mixes in the injection barrel. This aids in regulating the density and uniformity of the melted plastic, ensuring mixing is done well and no impedance of air in the material.

Effect of Back Pressure on Plasticizing and Melt Quality

The control of the back pressure directly affects the plastic melt quality as given herein:

- Temperature Control: The back pressure supports the continuous temperature of the melted plastic to show uniformity.

- Air Bubble Removal: The proper back pressure removes air bubbles from the melt to ensure that there are no voids or weak spots created.

- Mixing of Additives: Back pressure ensures that any additives or colorants introduced into the plastic mix uniformly.

Balancing Back Pressure for Optimal Results

There is a need to balance back pressure in injection molding to get optimal benefits. If the back pressure is too high, then there is a possible degradation of plastic material, thus poor-quality parts. Too little pressure, on the other hand, means inadequate mixing; air bubbles might form.

Manufacturers like KraussMaffei and Toshiba highlight the importance of precise back pressure control in their machinery. They use advanced technology to monitor and adjust back pressure, ensuring the best results.

Injection Pressure (Image Source: Science Direct)

The Role of Access Doors in Pressure Management

Access doors allow for easy access to the injection molding machinery, making it simpler to monitor and adjust pressures. By having strategically placed access doors, technicians can quickly perform inspections and maintenance, ensuring that injection, holding, and back pressures are always at optimal levels.

High-quality access doors, like the BA-MDS Medium Security Access Door, are designed to be durable and secure. They provide easy access without compromising safety. These doors facilitate regular maintenance, which is essential for preventing issues related to pressure.

Conclusion

Proper pressure management is critical to the production of quality parts in injection molding. All three pressures in injection, holding, and back pressure are important for their respective functions. Ensuring that the three pressures are in proper balance and control ensures the plastic components are free from defects and absolutely precise and durable enough to meet all customer design specifications with extraordinary effectiveness.

Share our story - the 2025 version is available

Feedback

Feedback